Substrates Increase On-farm Energy Production in Anaerobic Digesters

Farms that use substrates in their anaerobic digesters to produce biogas tend to produce more energy that those that do not, writes, Chris Harris, Senior Editor for TheCattleSite.The general trend is shown in a report on the use of anaerobic digesters on dairy farms in Wisconsin - the Wisconsin Agricultural Biogas Casebook, prepared for Focus on Energy by Joe Kramer of the Energy Center of Wisconsin.

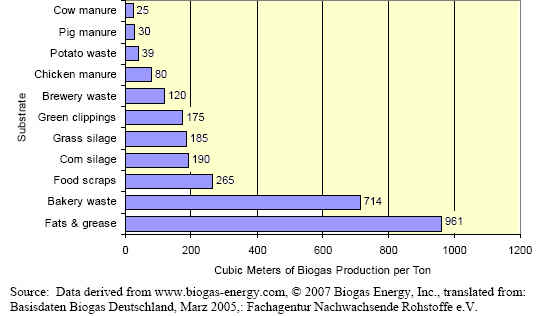

The report says that the anaerobic digestion of the manure produced on the farms - an extension of the process that is started in the cow's stomach - can be enhanced to produce the beneficial products of biogas that can be burnt to produce energy in the form of heat and electricity, liquid effluent and digested solids.

The liquid effluent that is produced can be used as a fertiliser with a low odour and can substitute for commercial fertilisers.

The digested solids are often used as bedding for cows, but can also be used as soil supplements.

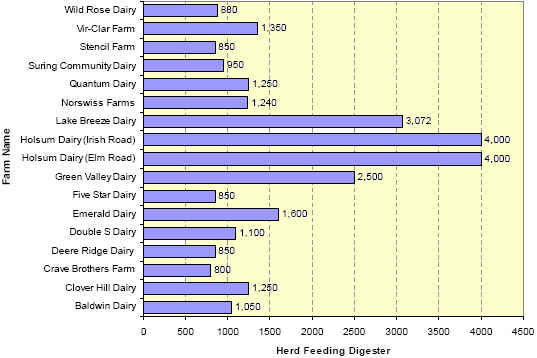

The report looks at the 17 farms in the state that have anaerobic digester systems. Of the 17 farms - all of which are dairy farms - five have two digesters.

The farms varied in herd size from the two largest having 4,000 head each and the smallest 800 head. The report says that the minimum number of cattle in a herd for successful use of an anaerobic digester is 500.

The methods of collecting the manure were monitored and in most cases it was collected by scraping with one farm using a gravity flow pit and another using a flush system.

The frequency the manure was collected varied on each farm from hourly to three or four times a day to continuous collection.

Most of the farms used the digested solids as bedding for the cattle although one used sand and another used kiln-dried sawdust.

The types of digester used on each farm also varied as did the manufacturers of the systems, with some farms using a mixed plug-flow system, others using a complete mix system, one with a modified mixed plug-flow system and one with a plug-flow system.

Once the biogas had been produced most of the farms ran the energy produced through a generator to generate electricity for sale and also producing heat. One farm has upgraded the gas to pipeline quality and another is flaring the gas. These two farms are planning to upgrade their systems to allow them to feed it into the natural gas distribution system.

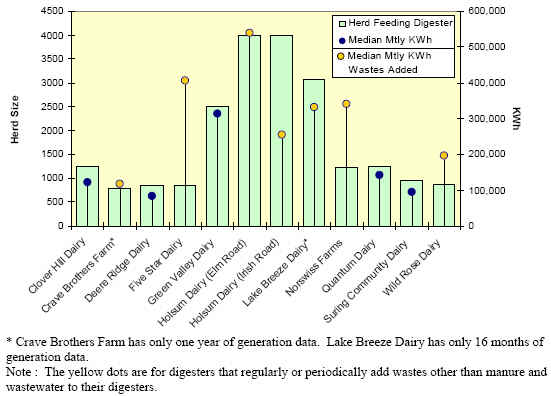

In all the report shows that the 17 farms in Wisconsin with anaerobic digesters are producing 7.3 megawatts of electricity. Each of the farms feeding into the grid has a purchase arrangement with the power company and this allows the farms to measure the average amount of electricity they are producing.

The report says that the anaerobic digester systems do not have gas measuring equipment so the amount of gas produced could not be recorded. However, it adds that this information is expected in future studies.

In all eight of the 17 farmers are adding substrates to the manure, wastewater and bedding in their digesters. Some of the systems are digesting off-farm food waste and they have made the biogas production part of their business model. The waste products that are being added include whey, industrial food grade grease, waste from food processing plants, corn syrup and the mouldy feed not eaten by the cattle.

The report shows that all except two of the farms where substrates were added, were producing about the monthly average amounts of electricity. Of the two that were not, one did not have a large enough anaerobic digestion capacity for the herd on the farm and the other was adding wastes because of inconsistent manure production because of other construction projects on the farm.

Further Reading

| - | You can view the full report by clicking here. |

October 2008