Building and Managing Super Calf Hutches

By John F. Anderson - Professor Clinical and Population Sciences College of Veterinary Medicine and Donald W. Bates - Professor Emeritus Agricultural Engineering College of Agriculture.

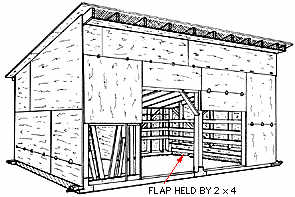

The super calf hutch is shown with half of the front panels in the winter position and half in the summer position. The drawing also shows the location of the head gate. At left is one of the end hinged doors to be opened when the building is moved in the opposite direction to expose accumulated manure and bedding. Use a spreader bar when hitching a tractor to the skids. This will ensure a straight pull on the skids.

Weaning of calves should occur two weeks prior to any grouping procedure. The super calf hutch, when it is properly located, prevents exposure of the recently weaned calves to more mature animals maintained under a wide variety of housing conditions. The capacity of this unit is eight calves to an age of approximately five months. Animals housed in this structure are exposed only to each other, thereby producing less stress and allowing a small number of calves to become acclimated to group housing. The net result is healthier calves that outperform calves reared under less desirable circumstances.

Calves at this age are often placed in facilities that severely challenge their immune status after the semi-isolation of a calf hutch. These facilities may be old, unused buildings, a barn lean-to or a pole barn, and in these structures they are usually exposed to older cattle. Further, competition for feed and group status precipitates stress. The net result of this move is usually pneumonia, which often requires treatment, and some calves may die. Surviving calves usually do not perform as they should following bouts with pneumonia. The greatest loss sustained by producers, however, is later in the animal's life. That is because surviving animals usually sustain lung damage, and they will never produce up to their genetic potential. Chronic disease severely limits genetic capability.

Year-Round Use

The super hutch is intended for year-round use and its design provides for sub-zero temperatures on windy days as well as on hot summer days when there is little air movement. To accommodate these variations in climate, there is a fixed opening in the space between the rafters in the front and adjustable openings in the back wall. In addition, the open front has hinged panels to restrict this opening under windy conditions. In winter, these panels eliminate the common problem of a north or quartering wind, which tends to whip into the building around the corners of the open front. The panels also provide protection from the south when strong winds blow into this relatively shallow open-front building. The center section of the front of this unit also has hinged doors that fold down to restrict the height of the center opening. In the rear wall there are five upward swinging ventilation doors extending the full length of the building. These doors are top-hinged specifically to minimize rain entry. Further, they are opened or adjusted whenever moderate weather indicates a need for increased air movement, and must be adjusted according to weather conditions. All rear ventilation doors must be tightly closed in winter.Movable for Cleaning

The super calf hutch is a semi-portable 12 x 19-foot unit built on skids. It is of frame construction, covered with plywood, and has a shed roof. Straw or other suitable bedding material is necessary, as in the calf hutch. Hinged doors are located at the base of the end walls running the full width of the building. These doors are intended for use only when the unit is cleaned. One end door, hinged on top (hinges are fastened to the raised sill) is secured in the open position. The sills are raised so that these end openings are unobstructed. The super hutch is then pulled in the opposite direction by a tractor that is hitched to a spreader bar between the skids. The spreader bar prevents damage to the skids when moving the building. The manure pack is left in place when the building is pulled away from the pack, and it is then easily removed with a front end loader. Moving the super hutch should not be attempted when the skids are frozen in place during extremely cold winter weather.Super hutches perform well in winter. These units have been tested under severe weather conditions with temperatures ranging as low as -20° F with a wind chill of -90° F. The calves in experimental units remained in excellent health and physical condition.

Feeding should never take place inside the super hutch because of calf space requirements. A further problem with inside feeding is contamination of bedding with manure and urine. During extremely windy conditions, temporary protection for the outside feed bunk may be necessary. Feeding takes place outside the super hutch in a yard formed by using movable steel gates or other portable fencing materials. The feed bunk and the water supply should be accessible to the animals through the fence. Self-feeders should not be used for animals housed in the super hutch because excessively high-concentrate feeds predispose calves to laminitis. This manifests itself later when post-partum heifers start on a lactating ration.

Ideally, a concrete slab 28 x 44 feet should be constructed to provide a floor for the super hutch and to provide paving for the outside yard. The outside yard must be paved for permanent use to avoid mud accumulation. The area on which the super hutch rests may be covered with gravel or crushed rock, but paving is preferable. Be sure to raise the ground level on which the super hutch and outside yard are located so that rain and snowmelt water will drain away. The concrete slab on which the super hutch rests should be sloped ¼ inch per foot toward the back. The outside yard should be sloped ½ inch per foot from the front of the super hutch to the front of the slab.

Suggested construction for concrete slab.

Should only half the slab be constructed initially, locate the water cup and electrical outlet to serve both slabs when the pavement is completed. Feed bunks should always be placed with the slope rather than across the slope, where they can act as a dam impounding snowmelt, rain and manure runoff.

Calf Restraint

An important feature of the super calf hutch is the restraint unit. This provides safety for both the animal and the caretaker during various procedures that must be performed on calves. A small, wooden, adjustable head gate is built into the left front of the building. This head gate is uncovered when the horizontally hinged front panel is lifted. It is always exposed in summer because the front doors of the building are then fully open.A swinging plywood gate is attached to a front post. This is vertically hinged (with three heavy L hinges) and it forms a chute which directs the calf into the wooden head gate. The calf being examined or treated is thus firmly restrained between the gate and the outside wall. This feature prevents injury to the calf and also provides safety for the caretaker or veterinarian standing outside the gate. From the veterinarian's standpoint the restraint feature permits safe, easy, efficient handling of animals. Early, accurate diagnosis is contingent upon adequate, safe restraint of animals.

You may find one or more super calf hutches to be a practical way of providing housing after calves have outgrown individual calf hutches. These structures provide excellent housing conditions for animals up to five months of age. Succeeding moves out of the super calf hutch should be to naturally ventilated buildings of suitable design essential for animal health. This procedure permits the calves' continued growth and development, thereby enabling the replacement animals to enter your milking herd at full genetic potential.

Blueprint

Front View and Crowding Gate Detail

Notes:

1. Adjust front and rear hinged panals to weather conditions.

2. For exposed locations partial closing of space between rafters at front may be necessary in winter.

3. Provide outside fenced areas for feeding and watering.

4. Swing up end panal then move building with tractor to clean.

5. Capacity - 8 calves to about 400lbs.

6. Anchor against high winds.

7. Close both sides of openings between rafters with 1/2" mesh screen to keep birds from nesting in rafters.

Rear View

| Approximate Bill of Materials | |

| Number | Description |

| 3 | 2 x 6 20 ft. rafter girts |

| 11 | 12 x 6 14 ft. rafters |

| 1 | 2 x 6 14 ft. split for crowding gate bracing |

| 2 | 2 x 6 12 ft. sill plates |

| 4 | 2 x 6 10 ft. skid plates |

| 20 | 2 x 6 8 ft. studs, top plates, knee bracing |

| 6 | 2 x 6 6 ft. nail supports, center door supports |

| 8 | 2 x 4 12 ft. flaps and rub boards on end |

| 6 | 2 x 4 10 ft. backwall rub boards |

| 2 | 2 x 2 10 ft. board across rear vent |

| 18 | 2 x 6 10 ft. studs, knee bracing |

| 9 | 2 x 4 6 ft. jamb, stanchion support, rub boards |

| 3 | 6 x 6 10 ft. posts |

| 2 | 4 x 6 20 ft. skids |

| 28 | 4 x 8 x ½" exterior grade plywood for sheathing, roof decking, crowding gate |

| 40 | 6" heavy-duty T-hinges |

| 1 | 3/8" bolt for stanchion hinge |

| 20 | door fasteners—vent doors |

| 6 | inverted T-shaped anchor plate ¼" x 3-½" x 11-½" (length) x 9-½" |

| 4 | ¼" x 3" x 5" metal plates for back side on skids to weld metal bar |

| 26 | 3/8" x 6-½" bolts—T-metal plates, back metal plates |

| 4 | rolls of roll roofing |

| 1 | 6" wide roll ½" mesh screen, 76" long |

| 2 | 9" x 11' x 6" canvas flap |

| 14 | 3" door hooks for closing front panels and opening manure removal openings |

| 4 | ¾" dia. bars 29" long bent and welded to metal plates for pulling |

| 1 | ½" dia. bar 10" long |

| 1 | 1/8" x 1" x 8' flat steel |

| 2 | 8" bolt, nuts (6) and washers (4) |

| 4 | 3/8" x 1-3/4" lag screws |

| sufficient nails for construction glue and dry-wall screws for gate |

|

1993