Robots Make Dairy Farms Run on Cow-time

Milking cows is a tying job and a commitment many farmers make at the start and end of each day. Øistein Thorsen, a US-based sustainability consultant, explores a Missouri farm and how it adapted to Dutch milking robots.My mother grew up on a dairy farm in Norway, writes Øistein. All through her childhood the family’s schedule revolved around milking times. A visit to friends or family would always end early as the cows would wait for no one.

Up before sunrise and never done before sundown - it was not the life my mum was after. But that, anyone with knowledge of the dairy industry will tell you, is the life of a dairy farmer. Until now.

Time Saver

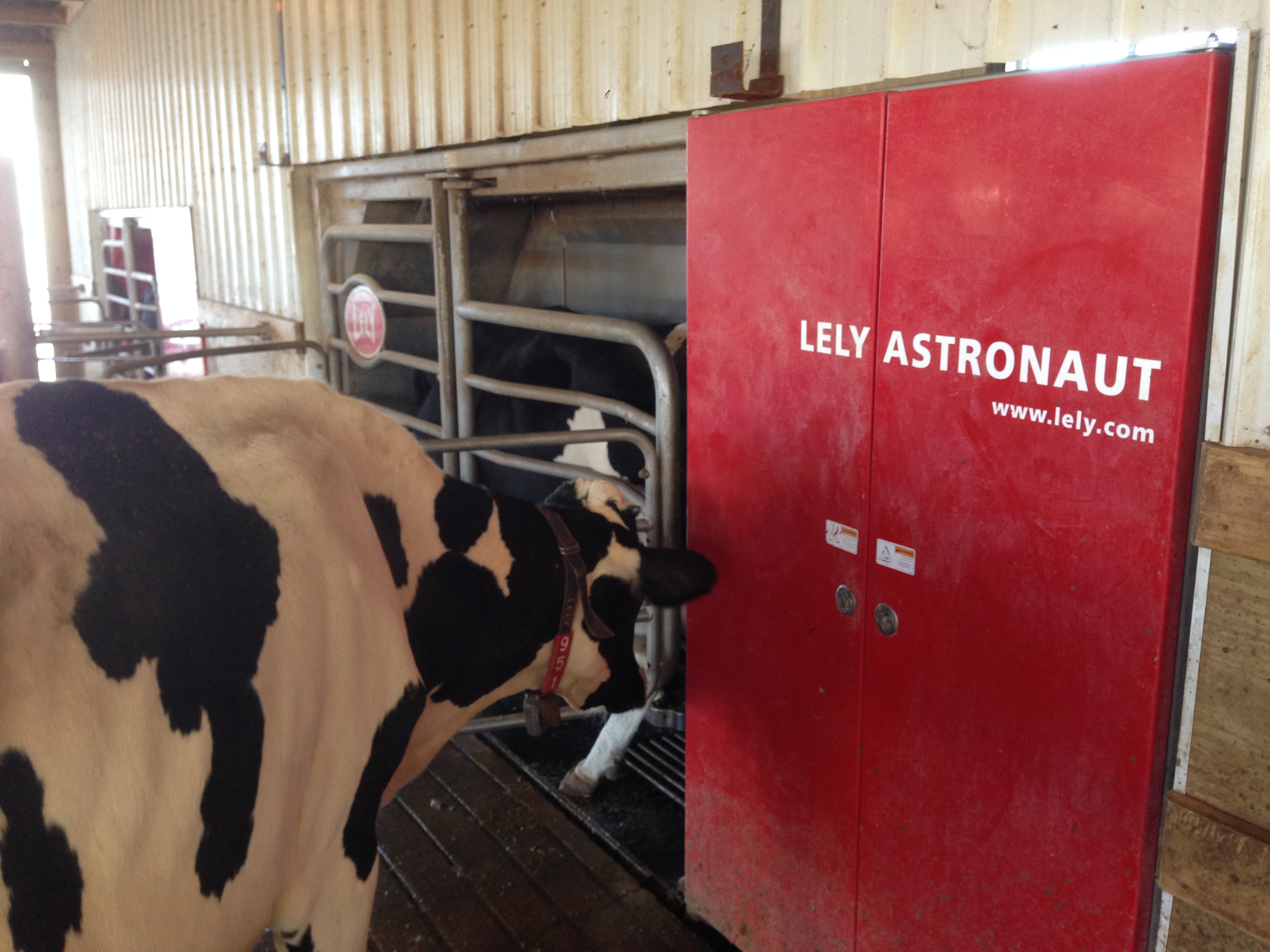

Introducing the Astronaut - a robotic milker from the Dutch company Lely. This robot, automatically milking cows when the cow wants to be milked, represents a revolution for dairy farmers and dairy cows alike. Let me explain how.

In New Haven, Missouri Rick & Cindy Scheer have invested in equipment that gives their farm an economic, ethical and technological edge. Rick’s father Gene, who is 66 years old and a soon retiring partner in the business, told me that they decided to go robotic for practical reasons.

Their old milking parlor needed changing and it seemed right to try something new. This was three years ago and he had never used a computer. Now, I watched him sit at his desk in the control room overlooking the barn, seamlessly operating three fully automated robots and bringing up on his screen huge amounts of data that the system generates on each cow.

The farm I visited was milking around 140 cows. On average each cow swings by the robot 2,8 times within each 24hr period, resulting in a total yield from the farm of close to 10,000lbs of milk per day.

It takes about three days to train the cows to use the robots. The farmer will lead the cow into the robot where a tray of highly nutritious food provides additional incentive for the cow to stay calm and come back. When they have learnt how it works the cows are free to roam inside the barn, relax on sand bedding, eat, drink or get milked when they want to.

In essence this is a high-tech, high-yield production unit designed around the cow’s schedule, needs and preferred behavior. And it works, judging by how calm the cows were even as I walked around taking pictures.

Lely – the producer of the robots – says on its website: “Successful robotic milking is a new style of farm management whereby the decisions are transferred from the farmer to the cow. It is all about early warning signals.” This they continue, allows farmers even with large herds to 'treat cows individually…and that results in improved cow health and reduction of feed cost,' just to mention a few of the benefits.

How the Robots Do It

The cows wear collars that allow the robot to track each cow and collect an impressive amount of data. If a cow tries to visit the robot too often to get her nutritious snack, the robot will know, withdraw the feed tray and lead the cow straight out again.

Similarly, the robot alerts the farmer if it has been too long since a particular cow was milked as this may indicate that she is not well. The collars also track the number of times a cow masticates during the day; a low number might indicate a health concern.

When a cow enters the robot to be milked, a 3D camera and laser technology helps the robotic arm to track the cow’s movements and locate each teat. It attaches the teatcups and then starts milking each quarter at a time, adjusting the pulsation ratings for each quarter. This results in both optimal milking and more gentle experience for the cow.

There is also a reliable system for detecting mastitis, and daily monitoring of fat and protein levels in each cow’s milk can be used by the farmer to optimize profitability of the farm and health of the herd by adjusting feed rations accordingly.

A brand new Lely Astronaut 4 costs just over $200.000 and can serve about 60-70 cows. The Scheers have three units, two new and one second-hand. They expected to pay off the initial investment in about seven years, however with the current milk prices and their competitive production costs Gene told me he thinks they will have recouped all costs in about 5 years.

Work Life Balance

Beyond the benefits to the farm business, the robot has given the family a sense of work-life balance for the first time. The robots work 24hrs a day and the oversight, upkeep and individual care for the animals can all be taken care of by one person throughout the day. If a machine breaks, a service professional will be on the farm within a couple of hours.

This frees up the farmers’ time to tend to their crops – they produce almost all the feed for the cows on their own farm – improve their overall business performance, and now and then even take the family out for a meal.

No more cutting visits short or being tied to the milking schedule all day. It’s a new dawn for dairy farmers, one even my mum would find appealing.