Slurry Application Management for Optimum Fertilizer Value

Volatile fertilizer prices experienced in the last year have contributed to a large increase in the value of cattle slurry to the farmer, writes Stan Lalor in a Teagasc publication.

Introduction

Trends in fertilizer nutrient prices since December 2006 are shown in Figure 1. The increased price of fertilizer nitrogen (N), phosphorus (P) and potassium (K) nutrients has resulted in the value of 1000 gallons (4.5 m3) increasing by 168% during this period.

Slurry nutrient content – “Fertilizer Replacement Value”

The N, P and K content of typical cattle slurry in Ireland is shown in Table 1 (O'Bric, 1991). The nutrient contents shown in Table 1 are mean concentrations, but a high level of variability (up to tenfold) will be observed in reality, owing to variations in animal diet, animal type and slurry dilution with water. Slurry variability is a major factor determining the reliability of slurry as a fertilizer resource, and every effort should be made to assess the nutrient content of slurry. This can be done using on-farm assessment tools, such as slurry hydrometer or N content assessment kits, or by having a slurry sample analysed in a laboratory. In any slurry nutrient content assessment, the importance of obtaining a well-mixed, representative sample is critical, and often difficult to achieve.

| Table 1. Typical dry matter and nutrient contents of cattle slurry in Ireland (O'Bric, 1991). (Alternative total N and P contents, and N availability are used under the Code of Good Practice (Anon, 2006)). | ||||

| Mean contents | Typical Availability | FRV/ m3 | FRV/ 1000gallons | |

|---|---|---|---|---|

| Dry Matter | 6.9 % | |||

| N | 3.6 kg/t | 30 % | 0.9 kg | 9 units |

| P | 0.6 kg/t | 100 % | 0.6 kg | 6 units |

| K | 4.3 kg/t | 100 % | 4.3 kg | 38 units |

The fertilizer replacement value (FRV) of slurry will depend on both the total nutrient contents, and on the nutrient availability for plant uptake. With the exception of soils with very low soil test P and K levels, P and K are generally considered to replace chemical fertilizer on a 100% basis; i.e. 1 kg of P or K applied in slurry is equivalent in fertilizer value to 1 kg of P or K applied as chemical fertilizer.

The N content of slurry is less available. Approximately 50% of the N in cattle slurry is present in organic substances, and is not immediately available for plant uptake. This portion of the N may become available over time, but its release is slow and can take many years. The other 50% of the N is present as ammonium (NH4 +), which is available for plant uptake, but can also be volatilised into the air as ammonia gas. Therefore, maximising the N fertilizer replacement value of slurry requires application management that ensures (i) high demand for N from the crop being fertilized and (ii) minimal losses of ammonia to the air.

Components of slurry value

At current fertilizer prices, slurry has a potential value of €9.17 /m3 (€41.25 /1000 gallons). While much of the focus on slurry value is emphasised towards slurry N efficiency, it must be remembered that approximately 88% of the fertilizer value is attributable to the P and K content (Table 2). Slurry should therefore be distributed around the farm in a manner that utilises fully all the nutrients in slurry. The values shown in Table 2 are only achieved if the application of chemical fertilizers is reduced on account of the slurry application. Applying slurry without adjusting chemical fertilizer applications will result in failure to achieve the potential savings indicated in Table 2.

| Table 2. The potential economic value of cattle slurry, and the proportion of value attributable to the N, P and K contents. | ||||

| N | P | K | Total | |

|---|---|---|---|---|

| Value / m3 | € 1.09 | € 2.39 | € 5.69 | € 9.17 |

| Value / 1000 gallons | € 4.88 | € 10.77 | € 25.60 | € 41.25 |

| % of total value | 12% | 26% | 62% | |

P and K fertilizer value

Each area of the farm will have its own specific requirement for P & K fertilizer. This requirement is normally determined by two factors. Firstly, the land use will be important. For example, the P and K requirements for a silage crop are normally higher than that of pasture that is only grazed. Also, the stocking rate of grazed pasture will affect the amount of P and K fertilizer that is required. The second factor determining the P and K requirement will be the soil test results. Soils with lower soil test P & K levels will have higher requirements for P & K fertilizers.

In order to reduce fertilizer costs, slurry should be applied to areas that have a P & K requirement. If slurry is applied to fields that have no P or K requirement while other parts of the farm continue to receive chemical P and K fertilizer, then there will be no savings in fertilizer costs.

Occasionally in the past, slurry may have been applied to fields that were more convenient to the farmyard and slurry storage tanks in order to minimise slurry spreading costs. As the value of slurry rises due to increased fertilizer prices, the distribution of slurry around the farm to fully maximise the fertilizer value of the slurry is worth re-examining. This may be particularly prevalent on outfarms that might have high P and K requirements, often deemed too far away to justify slurry transport costs. With slurry now being more valuable, the higher transport or spreading costs incurred may prove cost effective.

N fertilizer value

The N fertilizer value of slurry is dependent on the losses of ammonia to the air following landspreading. Approximately 90% of the total losses of ammonia will occur in the first 24 hours following landspreading. The level of ammonia loss is greatly influenced by weather conditions, with dry conditions, warm temperatures, low humidity, sunshine, and wind all increasing the ammonia loss.

Since weather conditions are generally cooler and moister in spring than summer, savings on fertilizer N costs by using slurry will depend mainly on the timing of slurry application. 1000 gallons of cattle slurry will be worth approximately 9 units of N if applied in spring (30% NFRV). However, the same slurry applied in summer will only be worth approximately 3 units of N (10% NFRV).

While spring application is generally recommended, it can often be difficult in practice due to soil trafficability or grass covers. Where spring application is not feasible, slurry application in the summer period (e.g. after silage harvest) should be managed so that the N efficiency can be maximised. Weather conditions at the time of application are very important, and slurry application should be targeted, where possible, to days when conditions are cool, overcast, or even misty. Hot days with sunshine should be avoided where possible.

Diluted slurry will also be more N efficient, as diluted slurry will percolate into the soil faster than thick slurry. Diluted slurry will also be washed off any contaminated herbage more quickly. However, while diluted slurry will be more N efficient, the N, P and K concentration will be reduced on account of the dilution.

Slurry application method

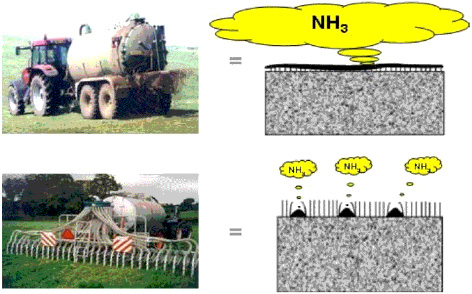

Slurry application method can also improve the NFRV % of cattle slurry. Low emission application methods such as shallow injection, bandspreader and trailing shoe apply slurry in confined bands / lines rather than broadcast evenly as with the conventional splashplate method (Figure 2).

The reduced surface area of slurry exposed to the air with the low emission methods results in reduced losses of ammonia, which means that a greater proportion of the ammonium in slurry is retained and becomes available to the crop. Experiments underway in 2006 and 2007 have attempted to quantify the fertilizer replacement potential of these technologies, and results are shown in Table 3. (Application method will not affect the P and K fertilizer replacement value of slurry.)

| Table 3. The effect of application method and timing on the NFRV, and economic value of cattle slurry applied to grass silage (Lalor and Schulte, 2008a; Lalor and Schulte, 2008b). | ||||||

| Application timing | NFRV % | kg N / m3 slurry (units/1000 gallons in brackets) |

Value N / m3 slurry | |||

|---|---|---|---|---|---|---|

| Splashplate | Trailing Shoe | Splashplate | Trailing Shoe | Splashplate | Trailing Shoe | |

| April | 29% | 39% | 1.05 (9) | 1.40 (12) | € 1.26 | € 1.68 |

| June | 10% | 21% | 0.36 (3) | 0.75 (6) | € 0.43 | € 0.90 |

The results shown in Table 3 are the mean NFRV% values observed in experiments on 3 sites in 2006 and 2007. The mean effect of the trailing shoe application method was to increase the NFRV of slurry by 3 units of N per 1000 gallons of slurry applied. The effect of switching application timing from June to April, without changing application method, increased the NFRV of slurry by 6 units per 1000 gallons of slurry. The largest benefit of 9 units per 1000 gallons was observed where slurry application could be moved from June with splashplate to April with trailing shoe.

Towards spring application

Based on these findings, the priority for slurry application management should be to apply slurry in spring rather than summer. While spring application is generally advised, the weather conditions at the time of application is the key consideration, and applications should be targeted towards days or periods of minimal sunshine and cool temperatures.

Attempting to capitalise on spring application and weather dependant opportunities for application requires considerable flexibility. The two main restrictions to slurry application are soil trafficability conditions and the grass cover on the areas designated to receive slurry. Application in summer is normally easily facilitated due to soil conditions that are normally dry at this time, and the absence of new grass growth in fresh silage stubbles. With splashplate, earlier applications that are targeted towards optimising the weather conditions on the day of application are more difficult, as such opportunities often arise on occasions when there is little or no spreadland area available with grass covers that are low enough to ensure that grass contamination will not limit the subsequent grazing palatability or silage quality of the pasture.

The trailing shoe offers advantages in this regard, as the slurry is concentrated in bands, with the result that the majority of the grass in the sward does not come into contact with the slurry. By reducing the grass contamination, the opportunity for more flexible application timing is increased as the consideration for grass cover is reduced. This means that on days when weather conditions that are ideal for slurry application arise (soil trafficability and reduced ammonia loss), more spreadland is available to the farmer with the trailing shoe compared to splashplate, as he/she is no longer restricted to areas with grass covers that are low enough so as not to affect subsequent grazing or silage quality.

The trailing shoe is not the only option to improve the opportunity for spring application. The umbilical application system, which pumps the slurry directly through a pipe system to a lowweight slurry application unit in the field, can be used to reduce soil compaction, as heavy tankers are avoided. Umbilical systems are now available with either splashplate or trailing shoe attachments. Also, with tanker application, tyre selection is an important consideration to aid soil trafficability and reduce the potential for damage that can result from machinery traffic on soils sensitive to compaction.

Cost-benefits

The trailing shoe is an expensive technology to adopt. In the absence of grant aid, purchase costs of trailing shoe tankers are approximately two to three times that of splashplate tankers of equal capacity. This means that the technology will be more suited to contractors rather than farmer owned units.

The quantifiable benefits to the farmer will be the economic benefits of reducing N fertilizer costs through the increased slurry NFRV from trailing shoe application. With a potential economic benefit of €0.44 /m3 slurry, adoption of trailing shoe on a 100 cow dairy farm (producing approximately 600 m3 of slurry) could save the farmer approximately €260 per year. However, this saving will be quickly absorbed by the increased costs of the trailing shoe. The economic benefit of switching from summer to spring application is greater at €0.80 /m3, and would correspond to €480 for the same farm. The switch in application timing from summer to spring with the same application method would be at no extra cost, so spring application should be a priority wherever possible.

The largest economic benefit of trailing shoe adoption to the farmer comes when spring application can be facilitated where it was previously restricted by splashplate application. In such situations, the economic benefits of both trailing shoe adoption and spring application are additive, and trailing shoe adoption is economically justified. However, the economic benefits of other means of facilitating spring application (umbilical system, tyre specification) are also worth considering.

Conclusions

- The P and K fertilizer value comprises the largest component of slurry value. Targeting slurry applications using soil analysis results is an essential component to maximising the value of slurry

- Slurry application that is targeted towards optimising weather conditions that result in reduced ammonia losses can help reduce fertilizer N costs. Such conditions are normally more prevalent in spring

- The monetary benefit from fertilizer N savings of switching to trailing shoe application without also switching application timing is marginal

- By reducing grass contamination, the trailing shoe system can increase the flexibility of slurry application, and help to apply slurry when timing and weather conditions are optimal

- Largest benefit of trailing shoe is seen when slurry NFRV is improved through both trailing shoe adoption AND switching application timing

- Other benefits of trailing shoe adoption, such as reduced odours, may be of significant value in individual cases

- Umbilical application systems, or improved tyre specification on tankers are also effective methods for improving the opportunity for spring application

November 2008